Very broadly speaking, climate-tech is the industry that deals with at least one aspect of climate change, and it can be mitigation, adaptation, monitoring, regeneration, or removal of greenhouse gas emissions.

The vast majority of the climate-tech industry still centers around the mitigation category. We see this in the problems and issues that companies are trying to solve and we see it in the financial attention those companies are getting, there is a staggering emphasis on investing in companies whose orientation is mitigating climate change effects.

Waste-to-energy is a pillar component in the climate tech industry because it plays a vital role in every one of those climate tech categories, and especially in mitigation and decarbonization efforts.

Waste to energy is offering huge opportunities and in a cost-effective way, that aligns financial interests with sustainability. This realization is gaining more weight and it is being reflected in the waste-to-energy market size.

If we look back on the last three years, we can see this vividly. In an analysis done by Fortune Business Insights in October 2022, they estimated the waste to energy market size in 2021 to be 32 billion dollars and projected to grow to over 44 billion dollars by 2029.

This market size does not grow in thin air, it’s the result of internalizing the benefits of waste to energy.

To frame this market in the right context, two general remarks are in order:

First, there is no magic bullet that can solve the climate crisis alone. It warrants consolidated efforts on everyone’s part, from a wide spectrum of topics that have to work together in a complimentary way.

Second, we need to keep in mind that just like in any other industry, the climate-tech industry includes a lot of background noises. If we examine how the industry behaved in the last three years, after COP26 we saw a big hype around climate-tech, we had the political attention and we gained momentum and budgets, and there were a lot of investments, many of them through SPAC and seed round investments, and then through the second quarter of 2022 things shifted. It’s not that some bubble burst, but it definitely felt like the honeymoon period was over investors as well as the industry realized that dealing with climate change involves serious technical and technological challenges that are not so easy to overcome. So from Q3 of 2022 we see that investments are shifting to Round A, there’s more emphasis on passing the proof of concept stage.

So with this mind, lets review how waste-to-energy can lead the way to decarbonize and mitigate the effects of climate change.

Waste to energy is a game changer for the most critical factor in mitigating climate change, and that is decarbonization. Here are two examples: decarbonizing the energy sector, and supporting decarbonization through the carbon markets.

First, lets look at the energy industry. There is so much going on in the energy market nowadays.

The energy industry, as we know, is responsible for most of the greenhouse gas emissions, mostly through the burning of fusil fuels. And in massive scales. The US Energy Information Administration published in early January in a press release its prediction for a record global petroleum consumption in 2024, referring to gasoline, diesel and jet fuel, that will average to more than 102 million barrels per day in 2024. So fuel is not going away anytime soon.

We also have dramatic rise in demand for electricity, projections are talking about increasing the demand from the current 27 tera kilowatts hour to 60 tera kilowatts hour in 2050, that’s just around the corner.

There is also rising demand for hydrogen as a source for energy, especially with respect to electric vehicles.

The world is going to need a lot of energy, and that energy is required to be clean of greenhouse gas emissions. Waste to energy plants can contribute to meeting those rising demands. The problem of waste can become the solution for energy.

The great thing about waste to energy is that it takes all the checklist we want out of our energy resources today, and adds another layer of eliminating the waste while we’re at it. If you think about waste as a renewable energy resource, it’s not that farfetched. Ironically, we can rely on having enough waste to generate energy more than we can rely on wind, or even the sun. We have SO MUCH waste it is a tremendous resource if you know what to do with it. And turning it to energy is a great way to go at it:

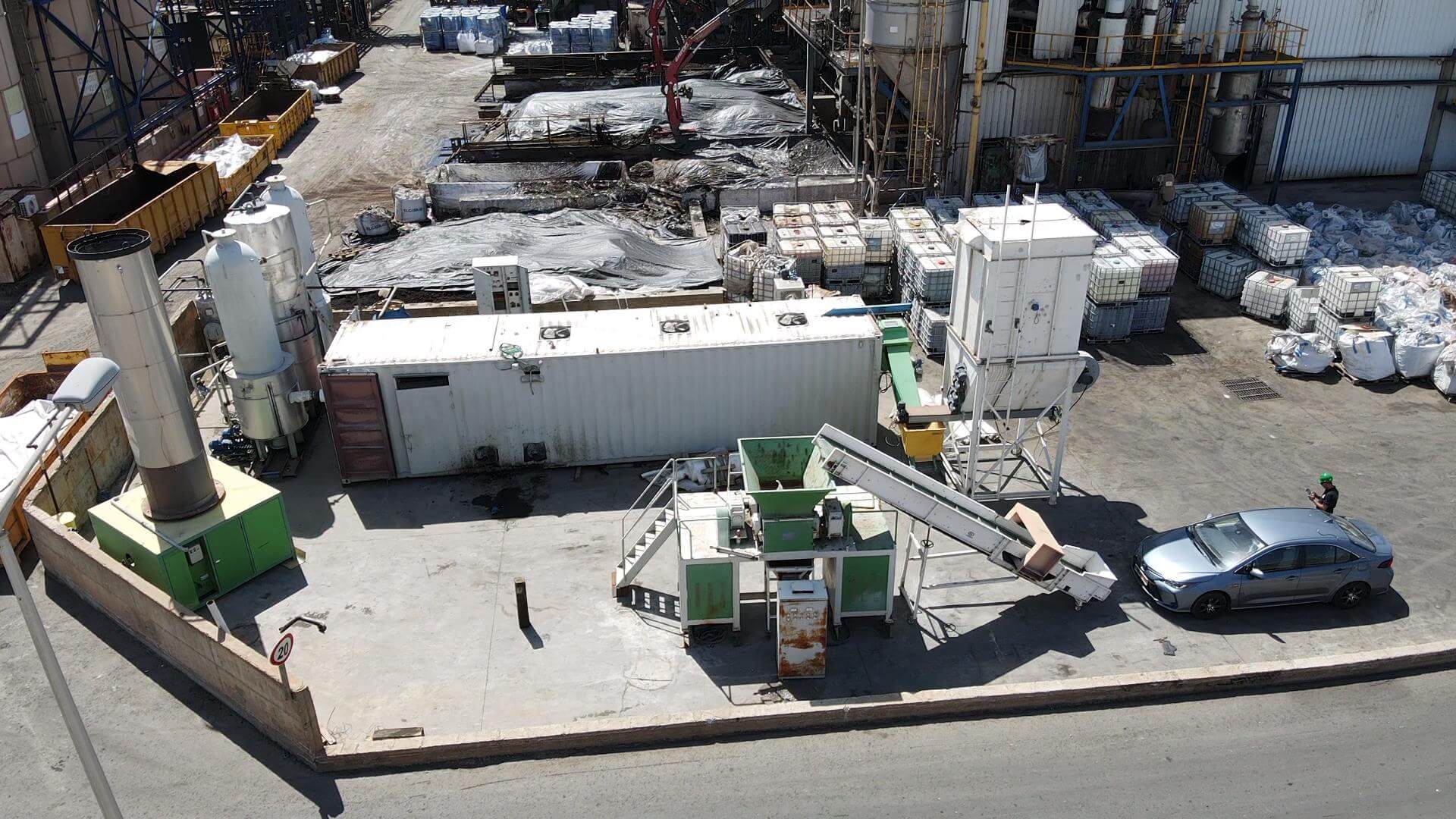

Using Co-Energy’s plants you can use 1 ton of plastic waste to generate 500 liters of diesel, or 1.78 megawatt, or 150 kilograms of hydrogen. So in terms of meeting the demands AND making it clean and green, waste to energy is a powerful tool.

Waste to energy can be a game changer for decarbonization efforts also when considering the carbon markets.

Carbon markets are a great way to incentivize decarbonization, and as we move forward with technological advancements, we see more and more options to engage in those markets. What used to be reforestation as the only option is opening up to exciting opportunities for capturing carbon. What the carbon markets are looking for is stability, and stability goes hand in hand with reliability.

Just like in any other market, carbon markets stakeholders look for clarity. Clarity and confidence in carbon trading will come from high quality projects that generate high volume of permanent carbon sequestration, and this is where waste to energy come into play with converting organic waste to biochar. Converting organic waste to biochar is a perfect use case for the carbon markets, as was expressed in the Wall Street Journal in their article about biochar and carbon credits recently published.

In converting organic waste to biochar we prevent the emission of methane and CO2, we create a carbon sink, and we turn waste into a tradeable commodity with various agriculture applications and so on. And this is a far better option than any other option for treating organic waste. Through Co-Energy’s biochar plants you get tens of thousands of sequestered carbon that is removed from the atmosphere. A removal that is considered permanent. This is the kind of clarity and confidence needed in the carbon markets.

Last but not least, it is important to address an issue that is sometimes overlooked but is really important and that is creating a safe work environment. We sometimes tend to talk in big titles about waste-to-energy and decarbonization etc., and when those words are translated to actions on the ground they involve hard working people doing a fantastic job in a rough environment, so when we as a community or a government choose which technologies we want to support, we need to also address the issue of how these technologies create a safe work environment. At Co-Energy this is something that we always keep in mind when we design and set up a project.

So to sum up, no matter what angle of the climate-tech industry you’re looking, whether through enhancing renewable energy resources, decarbonization efforts, smart waste management etc. The waste to energy sector has a lot to offer, and those few companies that have crossed the technological barrier can put forward projects that tie all the loose ends, present a solid business model and really make a change.