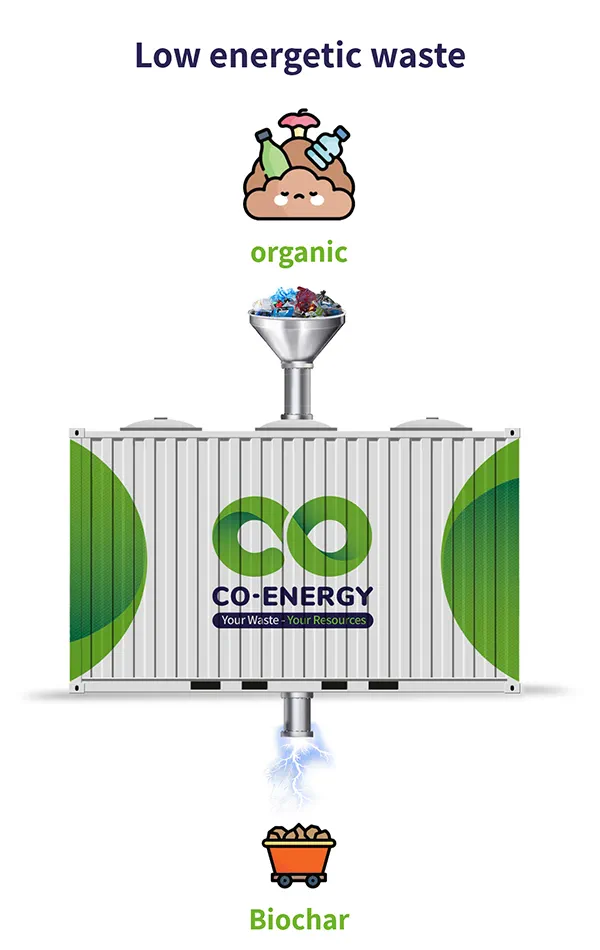

Co-Energy’s unique process combines several technologies into one in-line highly efficient and extremely cost-effective process. The process is a continuous in-line system from start to finish, which is far more efficient than a batch based process, saving energy along the way. The plant is equipped with an advanced control system with remote options for maintaining process stability based on non-homogeneous waste.

The output energy can be stored and released on-time (in accordance with the advanced requirements for the integration of renewable energies in the smart electricity grid). And as opposed to most waste treatment facilities, Co-Energy’s plant eliminate the need for pre-sorting and separation procedures.

uniqueness and competitiveness

The system combines multi-technologies into one in-line highly efficient and cost-effective process – far greater than other existing solutions

Continuous process as opposed to common batch based system – saving energy and lowering operation costs

Scalability – ranging from 0.5 ton/hour to 15 ton/hour and onwards, depending on client’s capacity of raw material

Advanced control system with remote control options – maintaining a stable process

Output energy stored and released as required – compliment with advanced requirements of integrating renewable energies storage to smart electricity grid

No pre-sorting is required – huge saving on money, infrastructure, time and manpower