Kelheim and Tel Aviv, July 5th, 2023 – ValVeri AG and Co-Energy Ltd., two leading companies in the field of CleanTech and renewable energy, have announced a strategic partnership and launched a joint venture. The joint venture will focus on developing projects to convert plastic waste into hydrogen. The first project of this partnership will be implemented in Germany at the H2-DonauHub Kelheim (Bavaria).

ValVeri AG is known for its expertise in the areas of CleanTech, renewable energies and especially hydrogen. The company accompanies various activities to promote a sustainable energy industry and is already implementing various innovative technologies in various operative participations.

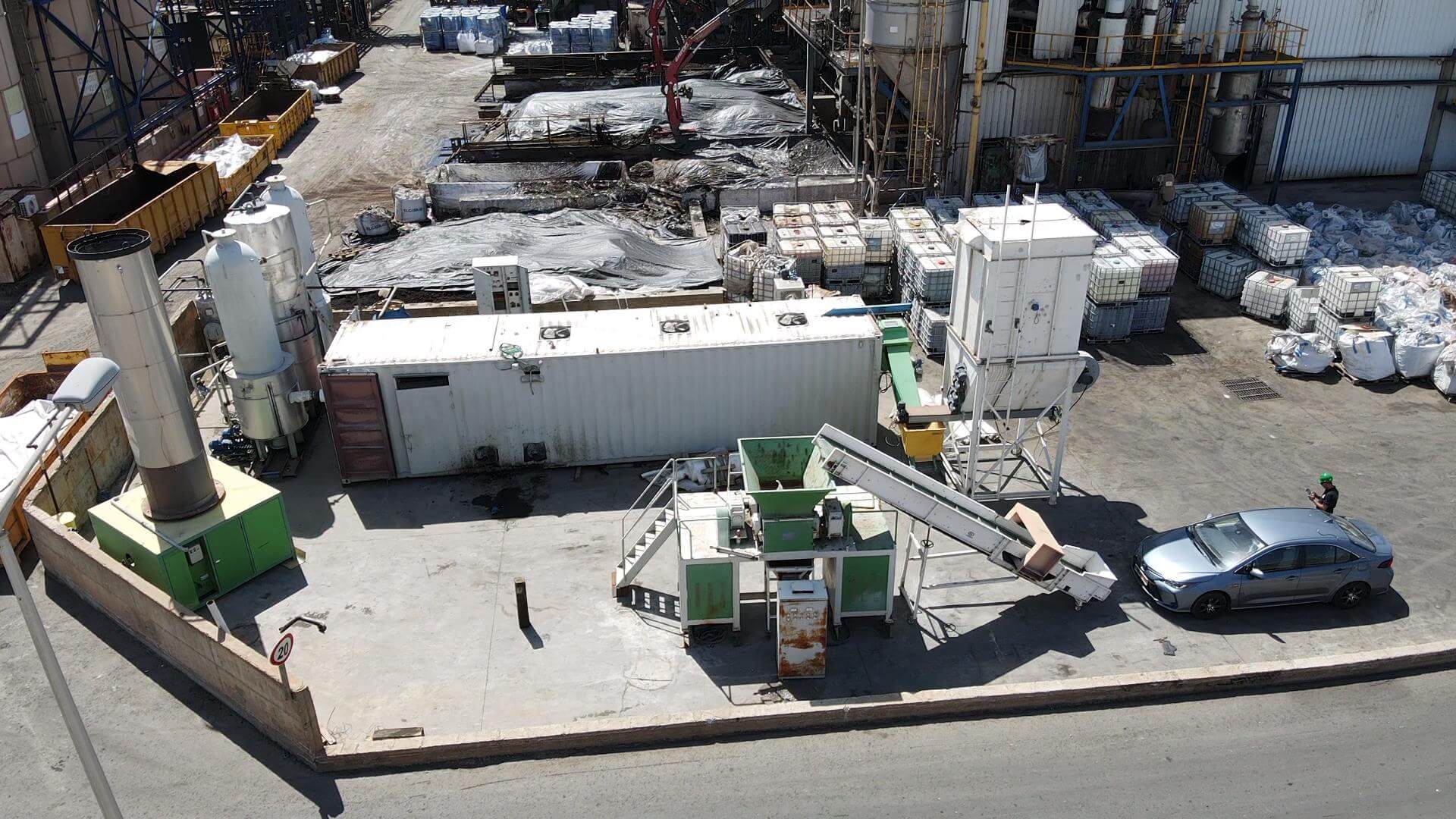

Co Energy Ltd. is an Israeli company specializing in the development and supply of technological solutions for generating energy from waste. With its expertise and experience, Co-Energy has established itself as a leading player in the field of sustainable energy.

Aviv Dekel, Acting CEO of Co-Energy stressed the importance of the collaboration: “Co-Energy is delighted to partner with Valveri and as each company brings their expertise and experience, this collaboration between Co-Energy and ValVeri will fundamentally transform the hydrogen market.”

Giorgio Karhausen, CEO of ValVeri, was also pleased about the cooperation and said: “I am pleased that we have succeeded in winning another innovative company from hydrogen technology for the cooperation. We want to use the excellent infrastructure in Kelheim to implement the joint venture with Co-Energy in the progressive environment at the H2-DonauHub.”

The first project of the joint venture will aim to convert plastic waste into hydrogen at the Kelheim site (Bavaria). This initiative will make an important contribution to sustainable energy supply and at the same time support the fight against plastic pollution.

The joint venture between ValVeri AG and Co-Energy Ltd. represents a significant step towards an environmentally friendly and sustainable future. The partnership brings together the expertise and resources of both companies to develop innovative energy harvesting solutions.

About ValVeri AG:

As a financial and management holding company, ValVeri AG is a leading company in the field of CleanTech, renewable energies and hydrogen. The company is committed to the development and implementation of sustainable solutions for energy generation.

About Co-Energy Ltd:

Co Energy Ltd. is a company specializing in the development and provision of technological solutions for generating energy from waste. The company has set itself the goal of creating sustainable waste-to-energy solutions that are cost-effective and reduce dependence on fossil fuels.

Press contacts:

Co-Energy Ltd.

Aviv Dekel – Acting CEO

Email: [email protected]

ValVeri AG

Anastasia Shafranskaya – Assistant to the CEO/Project Coordination

Email: [email protected]